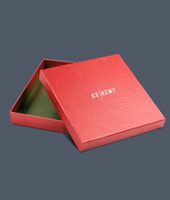

In the upcoming newsletters, we will present the procedures that we have started using this year in the process of the manufacturing of premium category boxes, and which all contribute to the fact that we can produce packaging products in supreme quality.

First part: Perfect edges

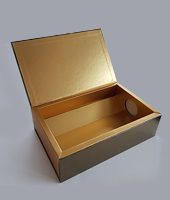

In the case of premium category boxes, our customers often request that the mounted boxes have edges as smooth as the boxes of mobile phones. In the past, we were unable to meet that demand.

In order to be able to satisfy these needs, we have recently bought a Kolbus NM101 grooving machine.

What kind of advantage does that offer?

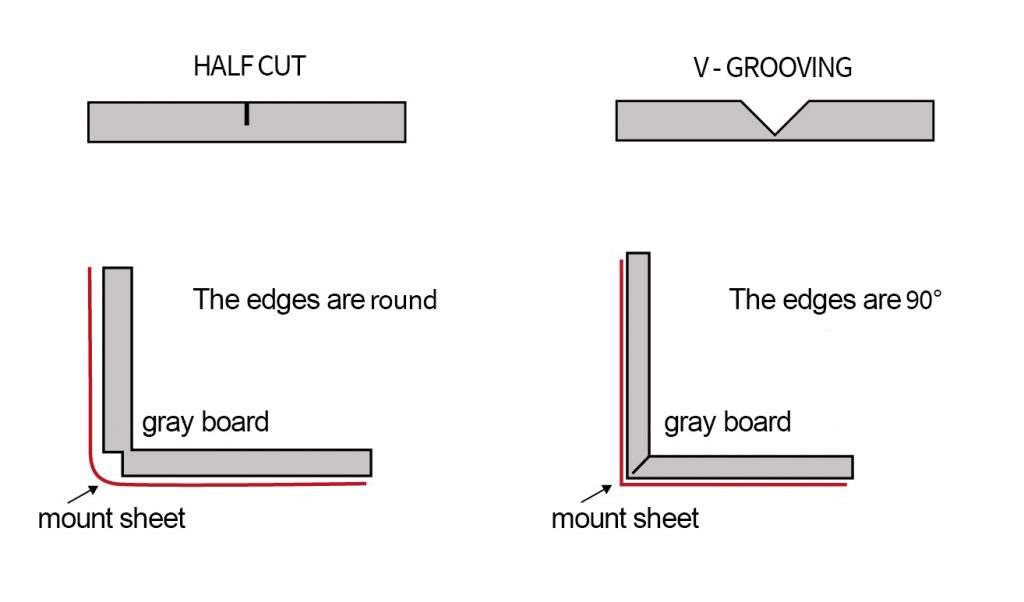

In the process of the traditional mechanical stamping, the non-bending chipboards, which constitute the skeleton of the box, are partly incised (scored) at the bends with a plane cutting machine. When the box is assembled, a small right-angled gap is created where the material is bent, thus making the edges somewhat roundish during mounting.

Instead of scoring, we use the Kolbus NM101 grooving machine to groove the 1–4-mm-thick non-bending chipboard in a V shape. Thanks to this V-shaped groove, the sides can be bent so as to form a perfect right angle, so in the process of the mounting, the mounting material adopts entirely the shape of the board. The tips of the box will be perfectly sharp, increasing the aesthetic impression and making its touch more pleasant.

More information about the production of premium category boxes

Make an appointment and request a quote

Tel: +36 1 414 3016

E-mail: export@keskenyprint.com

Leave a Reply