Below we will present some gift boxes through which we can demonstrate the unique formal and surface treatment procedures we can execute. With that we wish to inspire you and give you some ideas in terms of design in case you are considering gift box production in the future.

PHot foil stamped top-bottom box

The finished size of this unique gift box is 278x174x78 mm. The 2mm non-bending chipboard is mounted with 120g Wibalin natural black paper. For the top, 120g Rives design creative paper is used to mount the non-bending chipboard. Its form and clean colours lend elegance to the box, which is further enhanced by the silver foil stamped logo on the top.

For more information on the product, click here

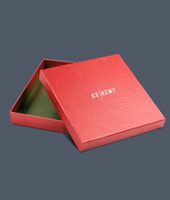

Embossed top-bottom box

This chocolate box goes to show that the simplest form can also be refined in appearance. 1.5mm non-bending chipboard is used for the top and the bottom, mounted with white 130g Peylin paper. After mounting, the foil stamped brand name is put on the finished top. The grey board is pressed during foil stamping to achieve a 3D embossed effect.

For more information on the product, click here

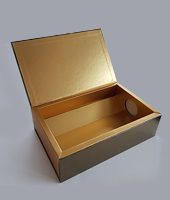

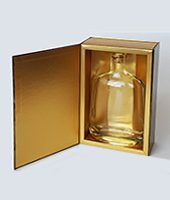

Magnetic box with flanged bottom

The technical design of this jubilee-edition box was carried out by Bonex Kft. The box is composed of two parts: an external mounted board and an internal flanged bottom. For this box, 1.5mm non-bending chipboard is mounted with a 170g gold foiled matte slick paper coating. It is printed with monochrome black, and the print receives a fine layer of hybrid varnish – that is how the somewhat grainy-looking surface is achieved. For the flanged bottom, a thicker, 300g SBS Invercote G cardboard is used, coated with gold foil. The insert is made from the box’s own material. Perfect closure is assured by magnets. The magnets are hidden in the upper part of the board while the counter-pieces are put into the bottom of the flanged part.

For more information on the product, click here

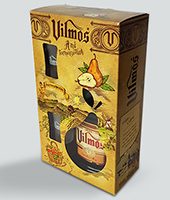

Drawer rigid box

It is the fine details that render this box truly special. As we could see in the above example, simple can be exquisite – and this holds true for more complex forms as well. The box is composed of several parts: an outer case, a drawer and an insert.

The frame for the outer case is made from 1.5mm non-bending chipboard. 120g black Wibalin is used for coating, which is printed with 2 layers of white cover, so as to make the Pantone-brown print (shown in the picture) impeccable. The inscriptions and the logo receive a copper foil stamp before embossing.

The drawer is manufactured from the samematerial as the case. A black satin ribbon is placed in the drawer to facilitate its pull-out. The insert is made from a thicker, 300g GC1 Arktika cardboard, printed with Pantone colour.

For more information on the product, click here

Collapsible rigid box

This packaging is highly practical. The box closes magnetically. It can be collapsed with a single move, and takes up little space. It is composed of two parts. The outer part is made from 2mm non-binding chipboard, coated with 150g matteslick paper. The coating material is printed with two colours before receiving a scratch-resistant foil. A 200-micron window film is glued behind the window on the top of the box. The magnets are concealed in the non-binding board of the sheet, so they are practically invisible. The side panelsare made from 350g SBS Invercote cardboard. The cardboard is printed and varnished on both sides.

For more information on the product, click here

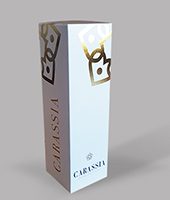

Magnetic rigid box

The box owes its exclusivity to its slightly oblong form and its magnetic closure. The contrasting choice of colours and the gold foiled motifs lend a powerful and vibrant look to the box. The frame is constituted by a 1.5mm grey board, mounted with a 150g four-colour matte slick paper coating. Here, too, the magnets are hidden in the non-bending chipboard. The box is manufactured with several types of inserts, so it is suitable for the packaging of products of various sizes.

For more information on the product, click here

Leave a Reply