We kick printing up a notch to get the most out of your product!

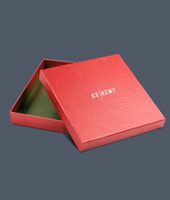

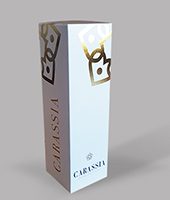

Make the appearance of your printed material and boxes more spectacular and exclusive by means of the Cold foil technology. Gives a spot-like special metallic shine to the surface or the small graphic elements.

Advantages of the Cold foil technology

The traditional way to create metallic appearance surfaces is hot foil stamping, which has some disadvantages beside a lot of advantages. During the process the metal film layer is squirted on the already printed foil by a cliché. Due to the preparation of the cliché the production is time-consuming and may be more expensive than expected.

This traditional method cannot be applied economically on continuous, big surfaces or in case of stamping widely separate points on the surface of finished products due to the technological characteristics of the stamping cliché, as in these cases the cost of the cliché is very high, and feasibility is questionable. In case of full tone homogeneous prints it can only be determined on the basis of a prior consultation whether the product can be implemented by hot foil stamping.

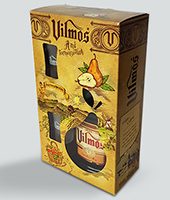

The Cold foil technology offers a perfect solution to the cases when we would like to achieve metallic shine on a large surface area, or we would like to highlight small details. The great advantage of the technology is that the metallic layer is applied on the sheet during printing, not after printing. As a result, we are not only able to achieve a unique metallic (silver or gold) effect, but it is also possible to print over it, this way metallized surfaces of any color can be created.

Overall, this process gives a large degree of freedom during graphic design. It can be implemented with a high degree of accuracy, from the line thickness of 0.15 mm to full surface. The costs of the process are not particularly high, it can be economically applied even in case of small orders. In addition, the plus expenditures may pay off due to the increased marketability.

In which situations may Cold foil technology be applied?

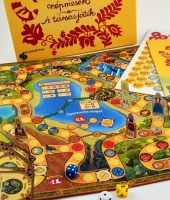

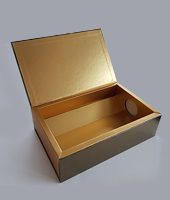

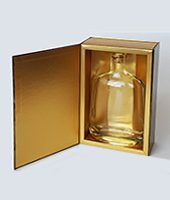

The typical application areas of Cold foil technology are decorative boxes, greeting cards and postcards, eye-catching one-off prints with high aesthetic requirements (invitation cards, business cards), but it is also applied on book covers, exclusive brochures, on the front page of magazines, and on the packaging of more ordinary products (chocolate, medicines). It is considered a mean which extends planning opportunities. It may decorate, highlight or render printed publications brighter or more elegant, depending on the use.

For further information about Cold foil technology please contact our colleague Katalin Nagy on the details provided below:

E-mail: k.nagy@keskeny.hu

Leave a Reply