Previously we have already explained the potential use of cold foil technology. It has been demonstrated how special a product can become – let it be a packaging or printing product – with the cold foil process.

Now let’s have a look at the potential of this technology from the designers’ perspective. Let us see what you should pay attention to in preparing graphic design and how to exploit the most from the potential of the process. We interviewed two graphic designers about their experiences with the cold foil technology. Zoltán Ökrös has long been using cold foil for design works. He often had the opportunity to use this procedure. György Protzner has recently been acquainted with this technology, encountering many new features during design work, to which you should pay attention to if you are planning to deal with cold foil works in the future. Since this is a more and more widespread and spectacular process, the following interviews are worth reading.

Zoltán Ökrös (graphic designer, Pozitív Logika Produkciós Iroda Kft.) has a higher educational degree in printing, but in the early 90s he became more and more interested in desktop publishing, graphic preparation and design. He has worked at newspapers, in advertising agencies, graphic studios, first as an operator but for over 12 years now as a graphic artist. His first cold foil work was to design and prepare the Varnish Catalogue of Keskeny Nyomda.

– Why cold foil is special as a procedure in your opinion?

Because it is a spectacular surface finishing procedure providing unique and easily customizable, highly variable appearance.

Technically not a time-consuming process, implemented in a single course with the traditional printing, so it is quickly and immediately visible for the client right at the starting of the machine.

It requires no extra tools, clichés, manufacturing procedures, but in practice can be used as a fifth color.

– What are the advantages of cold foil?

The spectacular and endless variability of colors and options. It produces a striking, high quality appearance, not to mention the “wow effect” from the client side.

The way it support the reception of image or unique design, either by highlighting, strengthening the details or placing in a new context the visible element, but can also give a completely new meaning to the image, either by using an unrealistic new form, or by a “not typical” element.

– What types of work fit the best for cold foil?

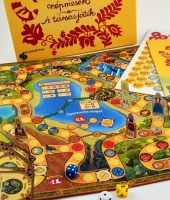

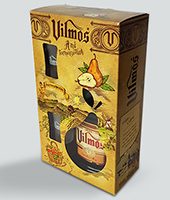

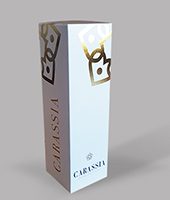

I think it can be used for any type of work where improving the feel of quality, uniqueness, attraction is the expectation, as it looks good on anything, from daily advertising materials to exclusive packaging.

– How well clients know this process?

With the publication of the Varnish Catalogue more and more people become acquainted with and looking for it. Recommendations and the description of available options are important, however, as it is still considered by many people as a traditional foil stamping process, and are not familiar with its plus potential. Once the clients get to know and experience the process, they surely become addicted to it.

– How easy is to prepare a coil foil work graphic-wise?

Relatively easy, it shall be imagined as a 5th color created in the given software that is even behaving like that during printing. It can be created throughout the entire printing surface, from fine swell-rule to larger filled flecks, but even 6 pt texts are also spectacular with it, and it can be used in 100% cover and as fine raster. It is overprintable, and due to the metallic effect and volume of the paint used over it variations of use are endless.

– What should be taken into special account in designing the graphics of a cold foil work?

Most importantly – and it cannot be emphasized enough –, it can do wonders with a picture just as it can make it wrong as well. The hardest thing is that you always have to consider the possibilities of the given picture, what are the picture details, shapes, areas, colors on which positive effect can be achieved, which adds something and gives extra value to the image. Unreasonable presence is to be rather avoided, meaningless “eye candy” makes the image cloudy. It is therefore important to align the use and form of cold foil to the possibilities of the given picture, there is no any general or strict rule for that.

It is also important that the foil has a specific (metallic, grayish) own color which makes the colors of the image darkeríin contrast to the white of the paper. It highly affects the lighter parts and tends to deteriorate it. Forexample, a face colorthe blue of the skyét or a light coloreddress. In order to avoid these mistakes, the downloadable of Keskeny Printhouse can serve as a huge help, where the best practices are demonstrated through examples.

One of the most, if not the most difficult thing is preparation and coordination with the client, since it is very hard, nearly impossible to reproduce the future appearance of the print. The printery can already provide the client with a proof to check how the print will look like. However, without this, even graphic designers can “only” rely on imagination, typically shown with a faint gray color, but it becomes completely visible for everyone in its real self (shiny metallic) as the machine starts to work, that is why the experience and the confidence of the customer is so important.

– What are the general feedbacks received from clients after a work has been completed?

Feedbacks are very positive, and generally followed by a new order.

György Protzner (graphic designer, C6 Média Kft.) has been working with graphics, designs for more than fifteen years. He spent ten years as a freelancer, previously he worked at magazines published on national level, PR and marketing agencies as well. He proved himself in almost all online and offline areas, let it be a small webpage, microsite, portal, flash and html banners, mobile apps, social media, logo, design, publications, magazines, books, product design.

When did you meet cold foil process for the first time?

About one and a half years ago. Previously I applied the well-proven embossing process as far as – really – metallic substrates were concerned. For this reason my first cold foil product was not too much different from the usual solution. Colored base, with some kind of varnish on it, then the metallic substrate, well-separated “as it has to be”. Shortly afterward, as I became aware of the substance of the technology, I became more confident to use it. In this process the presentation and the downloadable guides of Keskeny Printhouse served as an important help, where the various printing techniques and surface finishing processes are demonstrated through completed materials.

– How easy is working with cold foil graphics-wise?

Those who have experience in producing various printing files (meaning the participation in the creation of the final printing files to be submitted) will not have any difficulties.

Technically the procedure is the same as if we prepared a spot varnish layer, with the difference that in this case the final coating will glitter under and not “above the paint”. But those without experience or expertise can also become easily familiar with the technology, since the majority of printing specialists have the visual imagination that is basically required for this kind of work and that would help to put together the final form in mind. It is recommended however to prepare a cold foil proof for the first few works (there is already possibility to do that) or to ask for the opinion of a printing expert who has daily experience with the technology and who therefore has the knowledge on what will look good and what will not.

– What is the main advantage of cold foil in your opinion?

It is that metallic effect that none other pantone metallic color can produce, in fact if varnished subsequently, and secondly that I am free to use any color, since the metallic layer will be put under the paint, and in return, unlike in case of printing silver foiled arches, there is no need to deal with additional white underprinting.

– Cold foil facilitates or rather impedes the graphic designer’s life?

It is not much more challenging than a varnish layer would be – as I mentioned it above -, maybe it gets a little more adrenaline flowing, since any mistaken solution is

more visible than in case of a layer of varnish where mistakes come out only if turned into the light. It should be also noted that often it is the graphic designer who “has to sell” the design and the printed final product itself in terms of technology; not only freelancers but often the in-house creative teams are to propose a printing/bookbinding solution. In case of cold foil it is more difficult as far as only a small part of the client are familiar with this solution, being the foil+varnish+embossing “holy trinity” burned in people’s mind in the past decades.

– What do you think, when can be useful to apply the cold foil?

Anytime, where there is no need to metallize the entire substrate, where embossing cannot be applied due to small sizes, or where multiple levels/gradients are to be used instead of simple silver or available fix foil colors.

– Now that you have your first experiences with cold foil work, had you have any difficulties when you got stuck? Where could you find help to solve these difficulties?

The first major challenge I came up with occurred when I tried to use cold foil as a color gradient tool. Unlike the newer types of varnishes (for example hybrid effect) when it does not cause much trouble, in this case you need to pay attention to when the metal surface used as paint “is closing”, therefore you have to be very careful with the percentage value of trappings. Also in this case I received useful advises from Keskeny Printhouse, where I managed to solve any new task on their already completed and printed reference materials or by studying the file sources of their presentation materials.

If you have further questions about the cold foil process or you would like to participate in a symposium on varnishes, do not hesitate to write to us via the following e-mail address: k.nagy@keskeny.hu.

Our cold foil guide can be downloaded from <a title="here href=https://keskeny-nyomda.develop.weblapbolt.hu/app/uploads/2016/06/english_cold-foil.pdf

here.

Further information on proofing on metallized substrates is available here.

Leave a Reply