Extended sheet size, less paper needed, faster processing, perfect print from sheet n. 20. This machine stays 100% true to the idiom: Less is more!

Thanks to its unique qualities, our new Heidelberg Anicolor XL75 6+L-F offset printing machinery stands out among offset machines. The aim of this development was to improve the already superior quality of our services and boost our productivity while reducing our prices.

The main features of the machine:

- equipped with 6 printing units and dispersion varnish units

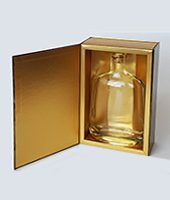

- suitable for cardboard printing; it can print on 0.8 mm-thick, approx. 500 g cardboard

- thanks to its unique “F” format (extended B2 format), the printable sheet size is 750-600 mm

- it has a special Anicolor inking unit with numerous advantages

The advantages of the Anicolor inking unit:

-

- it can print with very little technical loss, which results in significant quantities of material saved

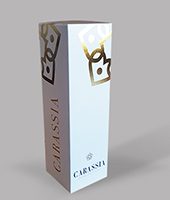

- it has excellent colour fastness; there is no colour instability thanks to the operation of this machine; the colour of the

sheets remains consistent even in the case of sensitive colours (e.g. 4-colour grey, dark blue shades) - there are no problems with the so-called “windowing”, i.e. when a blank part in the middle of a big page on a print appears in another

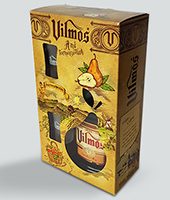

part of the sheet - the change of direct colours takes much less time, thus this technology allows us to print direct colour products quickly, efficiently

and for a reasonable price

With this development, our aim was also to be able to produce smaller series efficiently. We have experienced a steady decline in the number of specimens.

Our new development is an efficient and appropriate response to this trend, also benefitting our clients because we will be able to offer competitive prices even in

the case of a low number of specimens.

Just to give an example: the production of folders used to be somewhat complicated. It demanded 250-300 sheets of technical loss, and for direct colours, we had to

calculate with 40-50 minutes of setting time. With the new machinery, the technical loss has been reduced to 50-70 sheets while the setting takes only 15-20 minutes.

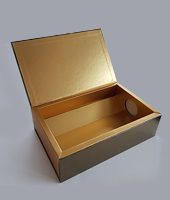

For what kinds of products do we recommend this printing machinery?

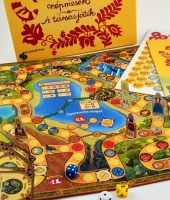

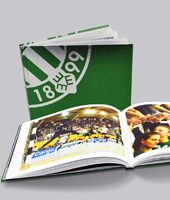

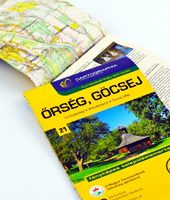

For flyers, folders, marketing print material and cardboard boxes printed in small series.

Leave a Reply