One of the most important goals of our Printing House is the production of high-quality products and the continuous increase of efficiency. The result of this is our latest investment, the new Bobst Masterfold box gluing machine, which is the perfect choice for special and complicated constructions and gluing larger corrugated boxes.

The Bobst Masterfold is the fastest, most automated box gluing machine currently available on the market. With very short setup time and reliable operation it ensures the continuous production of excellent quality products.

It is capable of gluing large sizes, even packaging materials die-cutted from 1100x800mm sheets.

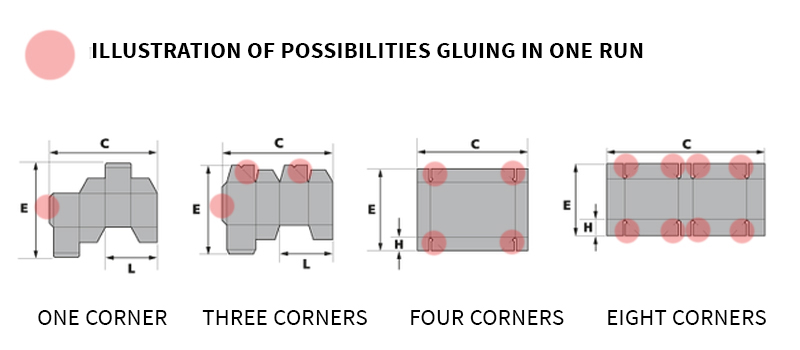

Its performance can reach 100.000 boxes per hour. With the help of a 90-degree rotation unit it can glue multiple corners of more complicated box shapes and special construction as well, in one run.

Thanks to the HHS unique code recognition, the Masterfold inspects the boxes during gluing and prevents the mixing of same sized boxes having different codes. This is very important in case of packaging materials for the food and pharma industries.

The photocells placed by the side of the glue dispenser nozzles checks the presence of the gluing and its position, ensuring the perfect quality and minimal waste.

The machine automatically recognizes the FEFCO and ECMA standards, this makes the setup of the gluing of these box types rather simple and fast.

The Masterfold is equipped with a complex security system, touch and movement protection, and motion sensors protect the workers from injuries. Cameras help the work of the operators and the whole machine can be controlled with a remote control.

With this investment we can not only guarantee the stable high-quality, but we can also reduce the lead times and waste disposal, and we are able to provide more “comfortable” workstations to our Colleagues.