The range of surface finishing treatments of Keskeny Printhouse has been expanded!

Our brand new MGI JETVARNISH 3D Evolution & iFOIL-L machine is able to create beautiful 3D effects, which enhance the visual experience and open up a new dimension to all printed projects. This machine opened the way for Keskeny Printhouse to apply treatments with 3D UV varnishing and digital gold foiling.

3D UV varnishing?..

3D UV varnishing is a revolutionary process, as a result of which an extra glossy varnish is applied on specific elements of the offset or digital prints using digital inkjet technology. The thickness of the varnish is optional; it can range from 7 microns (completely flat) to 232 microns thickness. This technology can not only be used for the application of embossed spot UV varnish, but by using gold or silver foil + 3D UV varnish conventional hot foil stamping can be replaced with it; it can even be applied to emboss hot stamped surfaces. This is a totally digital solution, which can save us time and money as it is not necessary to use a cliché or screen for the finishing treatment.

Types of products we can use it with:

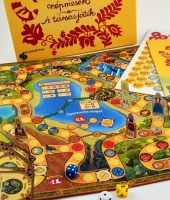

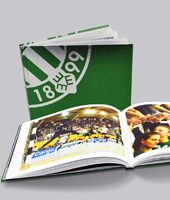

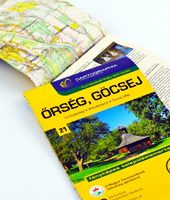

We offer our latest service to those who wish to develop their products and make them more special proposing a more creative and valuable solution to their clients this way. We recommend the treatment to the following products and effects:

- one-off prints, brochures

- business card

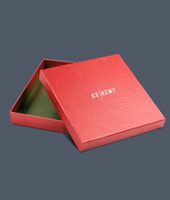

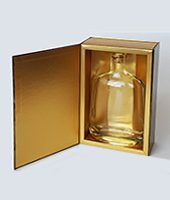

- luxury packaging

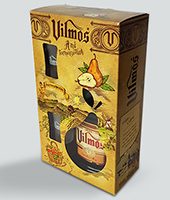

- packaging food and beverages

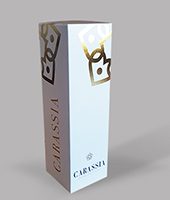

- packaging cosmetic products

- imitating fabrics, textures, woodgrain or other effects

- highlighting graphic elements

- conventional flat varnishing

- creating braille-effect inscriptions

Advantages of the treatment

- quick: it is not necessary to involve subcontractors

- perfectly accurate: scanner-driven settings

- super glossy: higher gloss compared to conventional UV varnish

- it can be used instead of embossing – without using clichés!

- instead if conventional hot foil stamping – without using clichés!

- environmentally friendly: lower energy consumption, less waste compared to conventional treatments, as there is no printing plate, screen, or cliché, using less input of raw material and plastic packaging material

Useful information

Some important data about the prints that can be produced by the MGI JETVARNISH 3D Evolution & iFOIL-L machine:

- maximum sheet size: 720×1200 mm, on which the size of the varnished design can be 510×1190 mm

- UV varnish thickness: within the range of 7-232 microns – a varnish layer of 42 microns has a quite spectacular effect on the graphic!

- thickness of raw material: minimum 135 gr (150 microns), maximum 800 gr (800 microns)

- the raw material has to have a coated surface: art paper, foiled surface, in case of paperboards the coated side. The technology is not applicable on moisture absorbent offset papers or on uncoated creative papers

- the printed sheet shall be foiled or treated with dispersion coating, as this way it will have a higher adherence and the finishing looks nicer on it

Factors affecting the cost

The calculation of the price of products prepared using 3D UV varnishing is based on several factors. We listed below the factors affecting the cost of the treatment:

- thickness of varnish layer

- fill ratio of the varnish (%): surface percentage affected by 3D UV printing. It has to be calculated separately in case of 3D spot UV varnish and 3D foiling

- surface of digital hot foil stamping, which determines the width of foil web necessary to production

If you have any further questions regarding the technology or the service, please contact our colleague.

Contact details:

E-mail: export@keskenyprint.com

Leave a Reply