If you are looking for quality colored printed corrugated board packaging material, you are on the right place! Thanks to the investments of the last few years, our printhouse gained valuable experiences in producing corrugated board packaging materials.

Many times, packaging materials made out of corrugated board are identified as brown, thick, unprinted or one color printed, large collection boxes. These are usually five-layer, EB or BC flute corrugated boards, which are usually printed directly in one or two colors, labelled with a simple logo or informative inscription – not in offset quality.

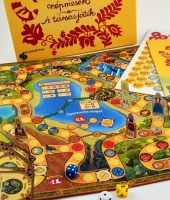

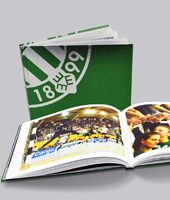

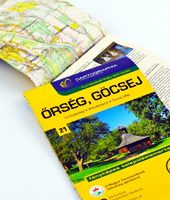

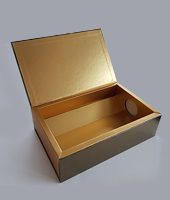

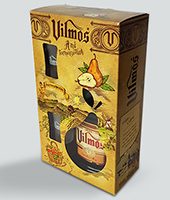

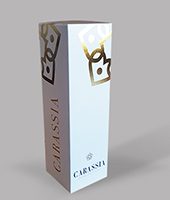

By the corrugated board packaging of Keskeny Printhouse we do not mean these massive, brown collection boxes, but packaging materials and boxes printed with the most unique colored graphic, in different shapes and with different finishing, when besides the outfit the protection of the product is equally important.

OUR STRENGHTS:

Below, we listed in which cases and why you should contact our company if you need custom transportation and storage boxes made of corrugated board for your product.

Wide variety of raw materials

Instead of three layer closed corrugated sheets we use brown or white open wave corrugated sheets in the manufacturing process. With our Bobst Foliostar laminating machine we glue the coating material (the liner) that best suits your needs on the fluting of the open wave.

We keep in stock more types of liners, which can be chosen according to the intended purpose of the packaging and the profile of the associated corrugated board:

- GD liner: cheaper, slightly greyish paper for the products where function and price are the priorities

- GC liner: nicer, wither, and higher-quality than GD liner

- Supreme Kraft liner: robust kraft paper which can be laminated in two ways: printing on its coated white side we get a premium white product, while printing on its uncoated brown side the result is a natural effect product.

- Graphic paperboards can also be used as liners, such as Alaska+ GC2 paperboard or SBS paperboard; the use of these leads to an even higher quality. In case of products laminated with graphic paperboard striping (phenomenon specific to corrugated sheets, when the surface is slightly striped on the flutes of the corrugated sheet) is less visible

Wide variety of shapes

Due to our 8-member team of designers, we are able to produce a variety of shapes. We design corrugated board packaging materials for different branches of industry, such as transportation and storage boxes for food industry products or retail sale etc. Our standard shapes are accessible on our website, while in case of custom design we offer a consultation with our colleagues.

We offer the freedom of designing

We print the liners first, and then we glue (laminate) them on the fluting of the open wave corrugated sheet, unlike the closed wave where the printed sheet is laminated on the whole surface of the closed corrugated sheet. Therefore, while using one layer less raw material, this kind of treatment also gives a wide freedom when designing the appearance of the box, as our well-known and popular extra surface treatments can be applied in case of liners similarly to folding cartons, for example UV varnish, hot foil stamping, embossing etc. Due to the extra surface treatments it is possible to produce special, durable, premium packaging.

Precise manufacturing

With our high-capacity laminating machine we are able to economically produce smaller batches of products (a few hundred sheets), but also large-scale works (one hundred thousand sheets), with a capacity of 5000 sheets per hour. The size range of our Bobst Foliostar laminating machine is quite big, we are able to work with any sheet size between the minimum size of 500×500 mm and the maximum size of 750×1060 mm.

TRY US, AND SEND YOUR REQUEST FOR OFFER TODAY!

Previous articles on the topic:

You can read about the advantages of corrugated cardboard mounting here

You can read about the manufacturing process of corrugated cardboard mounting here

Read more about tear strips and silicone tapes which can be applied on transportation and storage boxes here

If you have any further questions regarding the technology or the service, please contact us (see details below).

Contact details:

E-mail: export@keskenyprint.com

Leave a Reply