The cold foil technology opens new horizons in surface treatment.

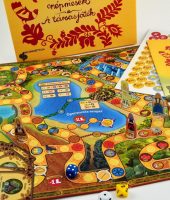

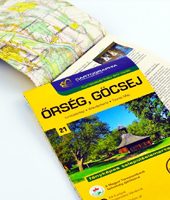

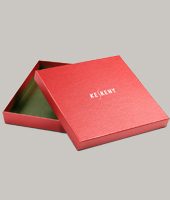

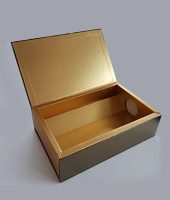

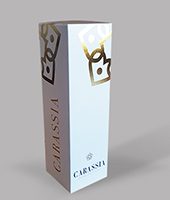

The procedure can be flexibly integrated into the printing process and is visually similar to hot foil stamping but offers a lot more possibilities by getting onto the print together with the picture material, so it can be overprinted with several colour shades, or it creates a surface that can be varnished and has a metallic shine. One of the most important marketing strategy elements these days is to create striking, different and unique products that attracts attention. Surfaces with a metallic finish please the eye, so the product suggests exclusivity and high quality.

Design options are almost unlimited, since Cold-foil works like a 5th colour, it can be a 100%, shaded pattern made up of very fine lines or a letter up to the size of 6pt.

We do not have to make compromises in terms of base materials either, since we can use paperboards of any size between the grammage of 70 g-400g/m2

A Heidelberg XL 75-6+LYYL-C nyomdagépünk hat nyomóművéből kettő szükséges a for Cold-foil technology. In the first printing unit we apply the glue (normal or UV drying) with a traditional offset plate to the desired design element. With the help of a module built onto the second print unit the very thin layer of silver is applied to the glued surfaces from the foil coil. Onto this we print the picture material from the remaining four print units. We varnish the print with the varnishing unit, if it is needed.

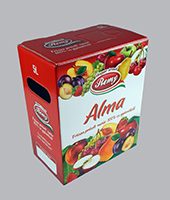

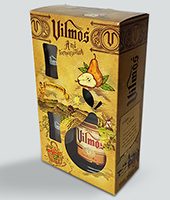

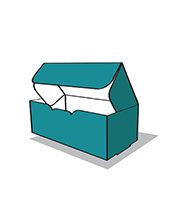

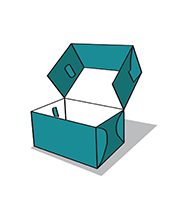

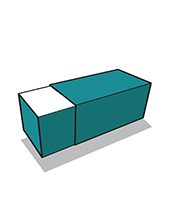

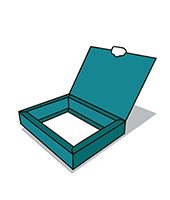

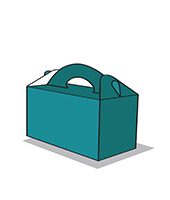

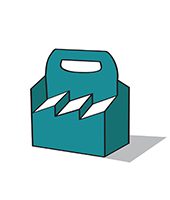

In the case of marketing print materials Cold-foil technology can have an outstanding role, but it offers great possibilities in the field of packaging, too.

ADVANTAGES OF COLD FOIL TECHNOLOGY:

- High processing speed and spectacular design elements can be applied even on full surfaces.

- It provides a surface which can be overprinted and coated.

- No stamping cliche is needed. While carrying out this process, you can use

- conventional consumables. (Offset plate, rubber blanket).

- It is not time-consuming to change for printing without foil.

- You don’t have to use an opaque white layer that’s why the print always reflects the real colour of the ink.

DISADVANTAGES OF COLD FOIL TECHNOLOGY:

- As opposed to stamping, it provides a less durable surface.

- As the first two printing units are used, hybrid coating can only be performed off-line.

Read the opinion of the graphic designers about the technical use and oppurtunities of the cold foil.

Our cold foil help can be downloaded on the following page.

For more information please contact the following address.

E-mail: info@keskeny.hu

>>

Válasz